Transcend Thermally Broken Entrances

Dawson introduces its Transcend Thermally Broken Entrances, designed to meet the ever-increasing stringent energy efficiency building codes without losing the beautiful aesthetic appeal or the customization that Dawson is known for.

Until now, thermally broken doors have only been available using limited extruded aluminum profiles.

Dawson’s Transcend thermal system utilizes internal pour and de-bridge extrusions using Azon Structural Thermoset Polyurethane, which acts as the door’s skeleton. A door pan is custom laser cut and bent to fit every project’s exact specifications and is then affixed to the sub-structure.

Transcend thermal entrances do not have any visible seams on the door or frame’s face, making our product the only one in the industry offering this option.

Find out why Dawson’s Transcend Thermally Broken Entrances make the most Energy Efficient Doors for custom commercial applications.

Read on to learn more about Transcend:

THERMAL BREAK IN DOORS: WHAT YOU NEED TO KNOW!

Transcend Thermal Performance

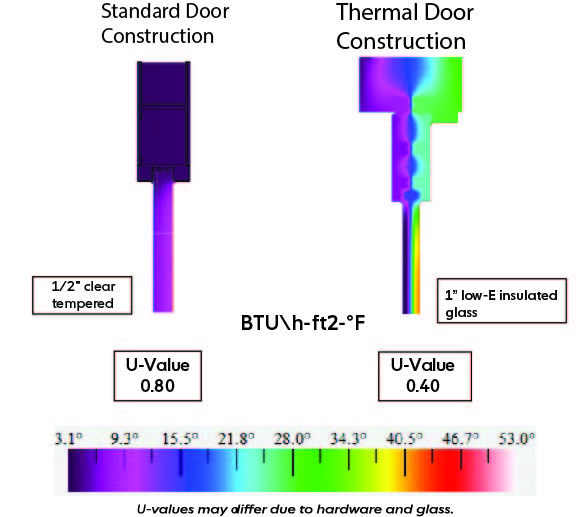

Figure 1 shows a comparison between a Transcend thermally broken door top rail and a traditional Dawson non-thermally broken top rail. The U-Value listed under each image represents the entire door system calculated using the respective construction methods.

The door on the left side, without the thermal break, has a calculated U-value of .80, which does not meet the current industry standard U-value of .77. The thermally broken door on the right side has a calculated U-value of .40, which far exceeds all current energy requirements.

The coefficient of heat transfer (U-value) was calculated by Dawson engineers using a simulation performed according to the NFRC 100 procedure and the ISO 15099 standard. THERM version 7.7.10 and WINDOW version 7.7.10 software developed by the Lawrence Berkley National Laboratory were used to perform all calculations.

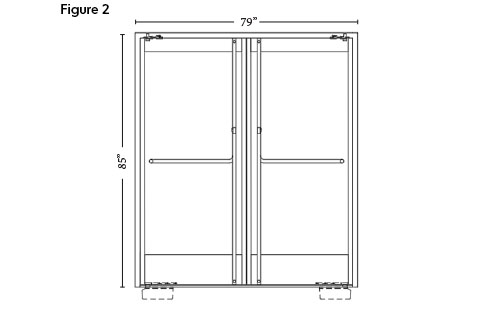

Figure 2 represents a complete Transcend center pivoted entrance. The overall size of the entrance is 79” wide x 85” tall to meet the NFRC standard model size. The total calculated U-value of this Dawson entrance is .40 (Btu/h ft2-F), and the SHGC is .208 (1” insulated Low-E glass was used in this calculation).

The calculations are based on NFRC 100 standards with an exterior air temperature of -.4° F, an interior ambient temperature of 69.8° F, and an exterior wind velocity of 12.3 mph. Calculation reports are available upon request for our standard entrances (pairs of doors with an immediate frame or single door with an immediate frame).

In the event that a project requires specific thermal analysis of a custom non-typical entrance, Dawson engineers can provide complete systems U-values upon request. This information will be submitted within our complete shop drawing submittal.

Dawson’s Transcend Innovation

Dawson Metal Company is one of only a few fabricators globally who can accomplish the level of complex engineering and close-tolerance fabrication that our clients demand. The company fabricates and forms the metal into high-quality architectural products in our door division and custom enclosures in our industrial division. All aspects of our business specialize in solving challenging projects to meet customers’ specific and demanding requirements. As energy compliance codes become increasingly stricter across the United States, the company is expanding its thermally broken range of doors which will all continue to be submitted to the rigors of in-house testing before being tested by independent certification authorities.